Whats A Pressure Transmitter

The expansion of automation in both mobile and stationary applications is increasing dramatically. As the efficient management of machines and systems becomes more and more dependent on integral electronic controls, there will be an increasing demand for sensors and transmitters.

The expansion of automation in both mobile and stationary applications is increasing dramatically. As the efficient management of machines and systems becomes more and more dependent on integral electronic controls, there will be an increasing demand for sensors and transmitters.

A pressure transmitter converts pressure into an analog electrical signal. Although there are various types of pressure transmitters, one of the most common is the strain-gauge base transmitter. The conversion of pressure into an electrical signal is achieved by the physical deformation of strain gauges which are bonded into the diaphragm of the pressure transmitter and wired into a Wheatstone bridge configuration. Pressure applied to the pressure transducer produces a deflection of the diaphragm which introduces strain to the gages. The strain will produce an electrical resistance change proportional to the pressure.

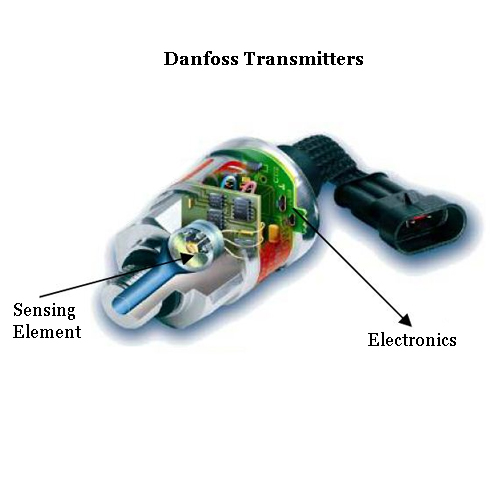

Danfoss pressure transmitters type MBS are based on a piezoresistive, monolithic silicon pressure sensor, protected by a stainless steel separation diaphragm and silicone oil filling between the diaphragm and the sensor

This type of pressure sensor consists of a micro-machined silicon diaphragm with piezoresistive strain gauges diffused into it, fused to a silicon or glass back plate.

The piezo-resistive silicon sensor, is the most suitable in applications with pressure peaks. The pressure overload is typically six times (max. 1500 bar) the measuring range and performs millions of cycles.The range of transmitters based on the thin film technology ensures exceptional accuracy, fast response time and long-term stability. Pressure transmitters are generally available with three types of electrical output; millivolt, amplified voltage and 4-20mA.

Millivolt Output Pressure Transmitters

Transmitters with millivolt output are normally the most economical pressure transducers. The output of the millivolt transmitter is nominally around 30mV. The actual output is directly proportional to the pressure transducer input power or excitation. If the excitation fluctuates, the output will change also. Because of this dependence on the excitation level, regulated power supplies are suggested for use with millivolt transducers. Because the output signal is so low, the transducer should not be located in an electrically noisy environment. The distances between the transducer and the readout instrument should also be kept relatively short.

Voltage Output Pressure Transmitters

Voltage output transducers include integral signal conditioning which provide a much higher output than a millivolt transmitter. The output is normally 0-5Vdc or 0-10Vdc. This means unregulated power supplies are often sufficient as long as they fall within a specified power range. Because they have a higher level output these transducers are not as susceptible to electrical noise as millivolt transducers and can therefore be used in much more industrial environments.

4-20 mA Output Pressure Transmitters

These types of transducers are also known as pressure transmitters. Since a 4-20mA signal is least affected by electrical noise and resistance in the signal wires, these transducers are best used when the signal must be transmitted long distances. It is not uncommon to use these transducers in applications where the lead wire must be 1000 feet or more.